Radion™ Plasma Sources

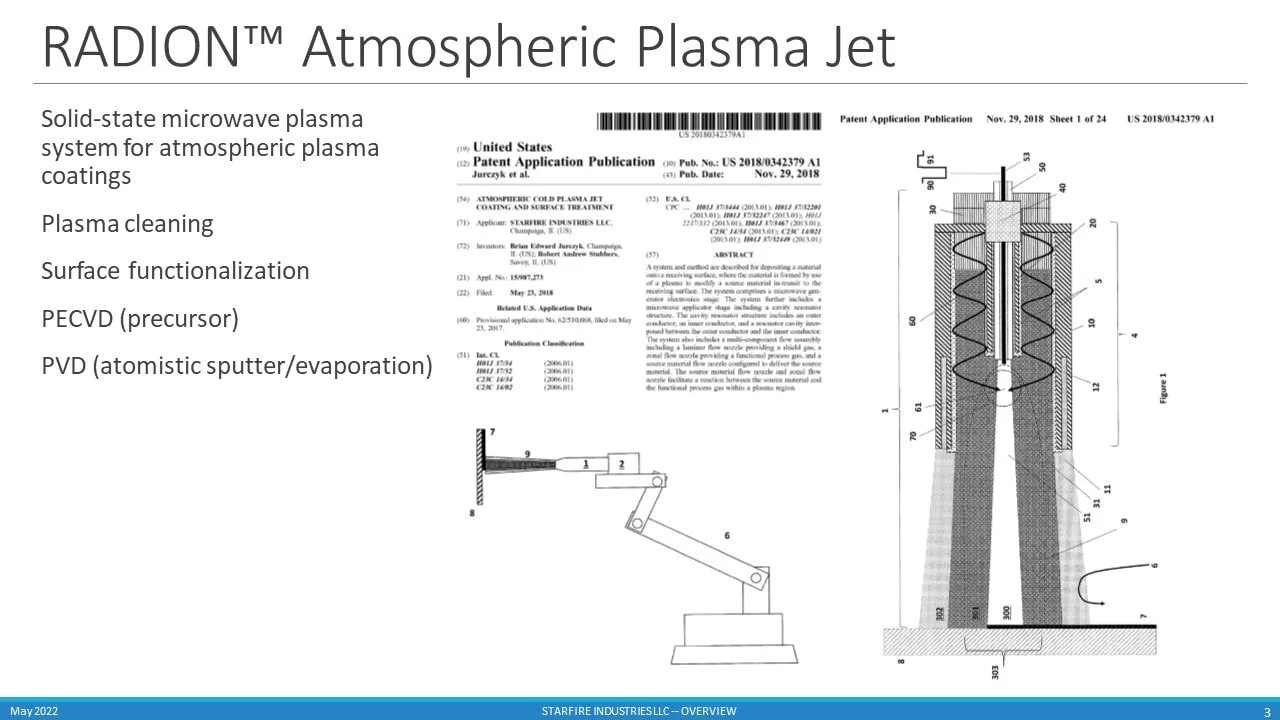

Patented RADION Microwave Plasma Sources

Surface Wave Processing

A surface wave plasma tool that reduces chamber cycle times with fast, damage free processing integrated on existing equipment.

Benefits:

Works with reactive gas chemistries

Damage-free processing for nearly all materials

Save at least ½ second per PEALD half-cycle

Fast pulsed (<1msec) or steady state operation

No matching network required

Compact size

Applications:

Plasma Enhanced Atomic Layer Deposition (PEALD)

Plasma Enhanced Chemical Vapor Deposition (PECVD)

Etching, Ashing, Cleaning

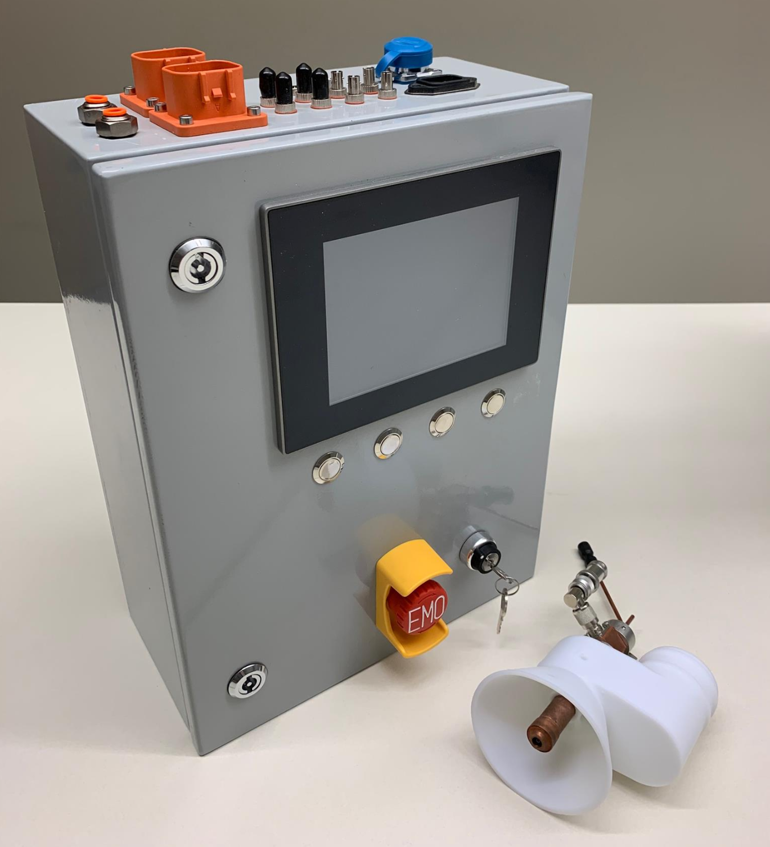

Atmospheric Pressure

A hand-held atmospheric-pressure source for surface treatment and functionalization, including adhesion and bonding promotion, hydrophilic/phobic control and texturization.

Features:

Many plasma and gas mixture options

Source head diameter ranges from sub-mm to cm-scale

Atmospheric-pressure processing reduces costs

Innovative dielectric barrier jet source

Drive electronics built into handle for added safety

Variety of applications, including: medicine, electronics, printing

WATCH: RADION Slideshow

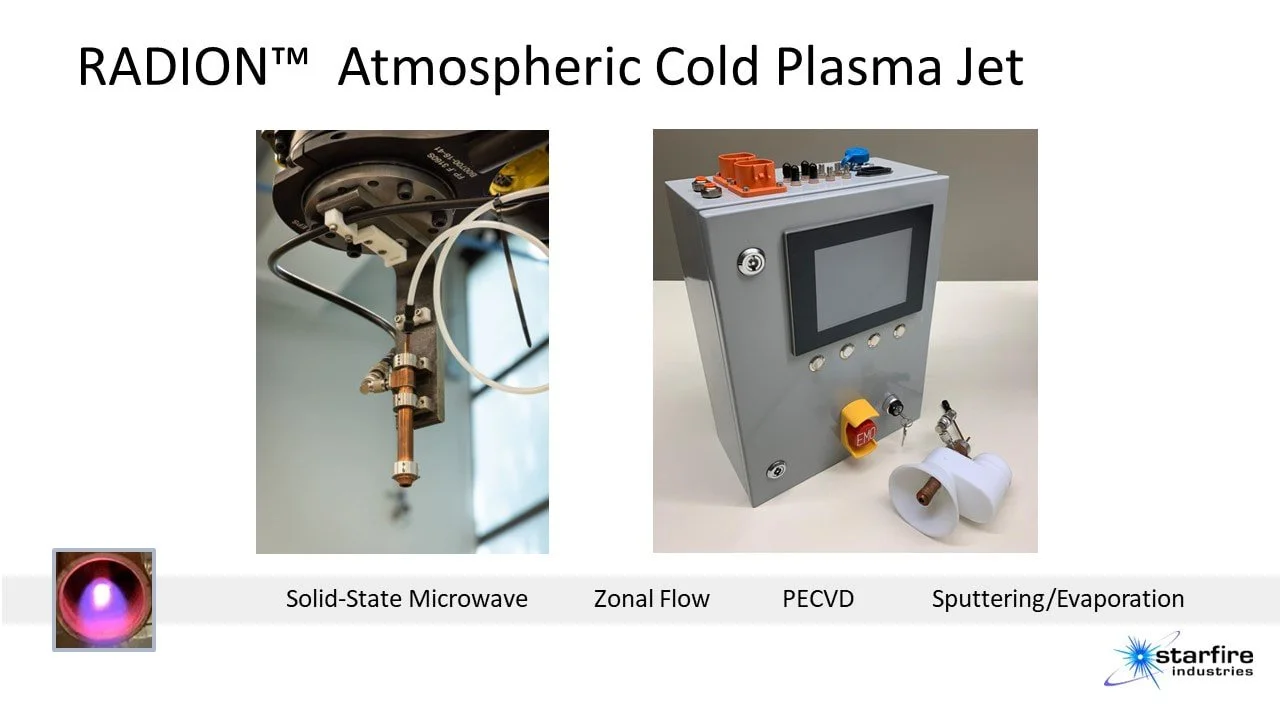

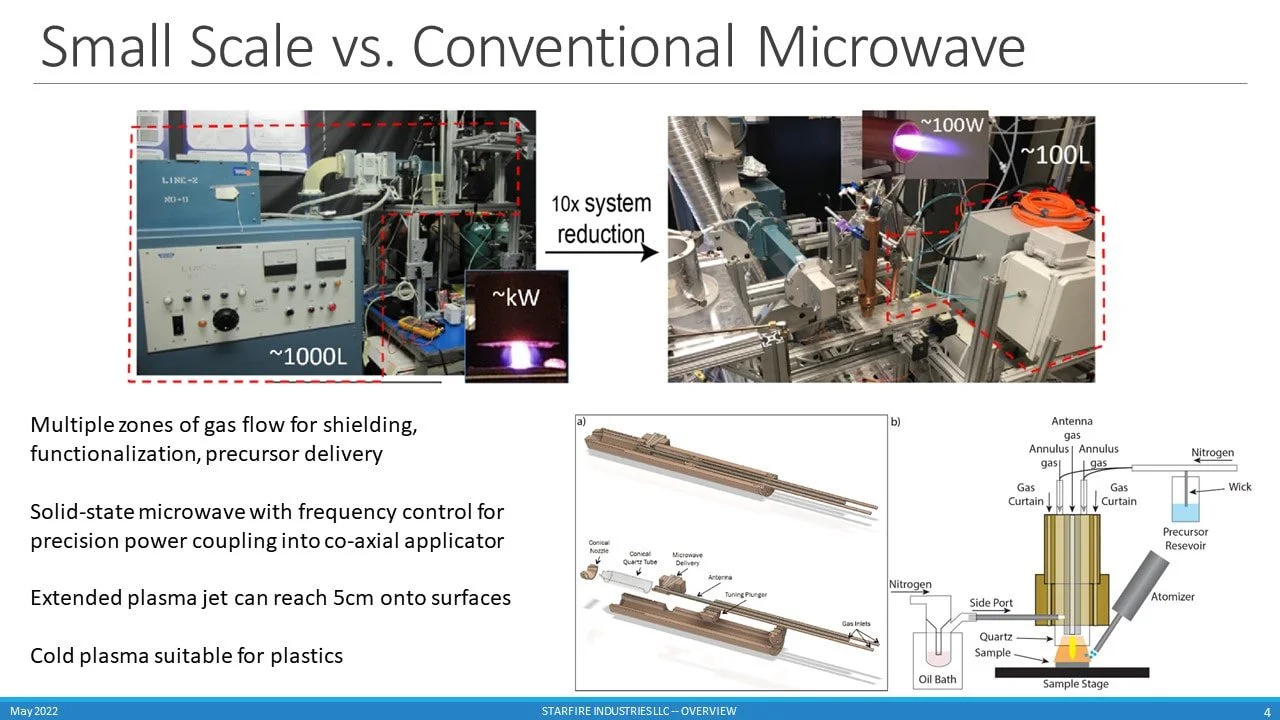

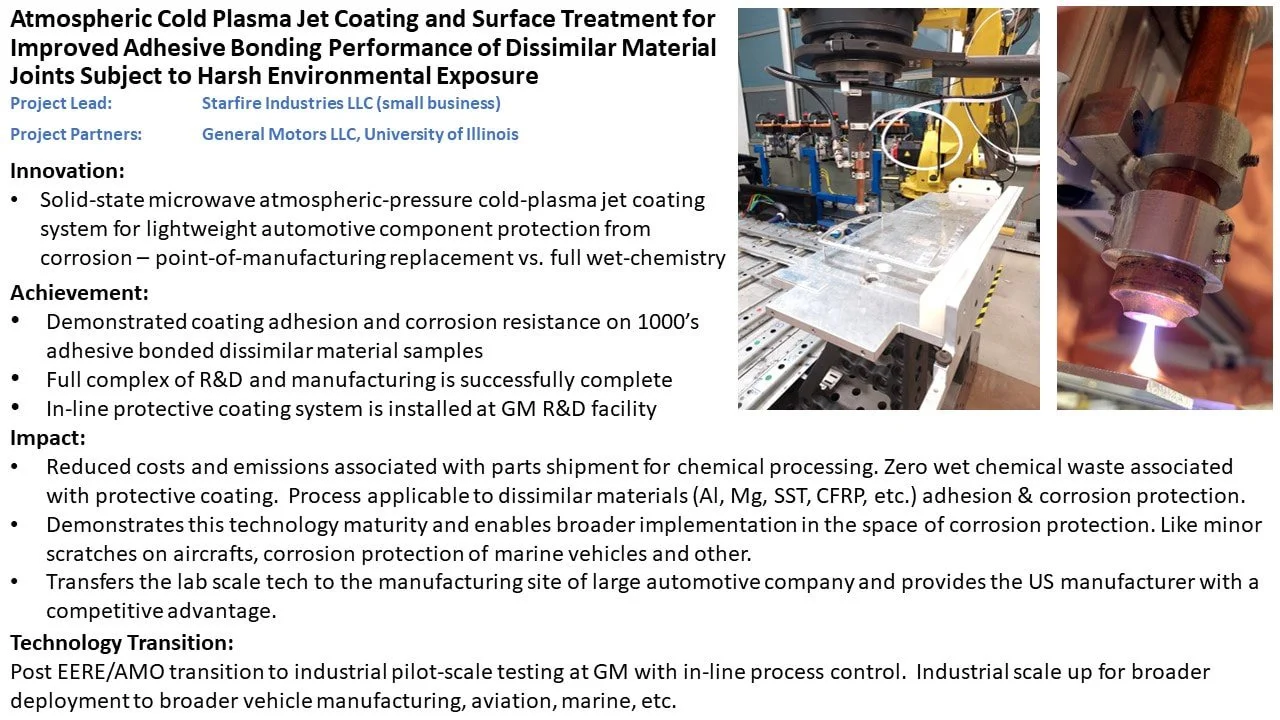

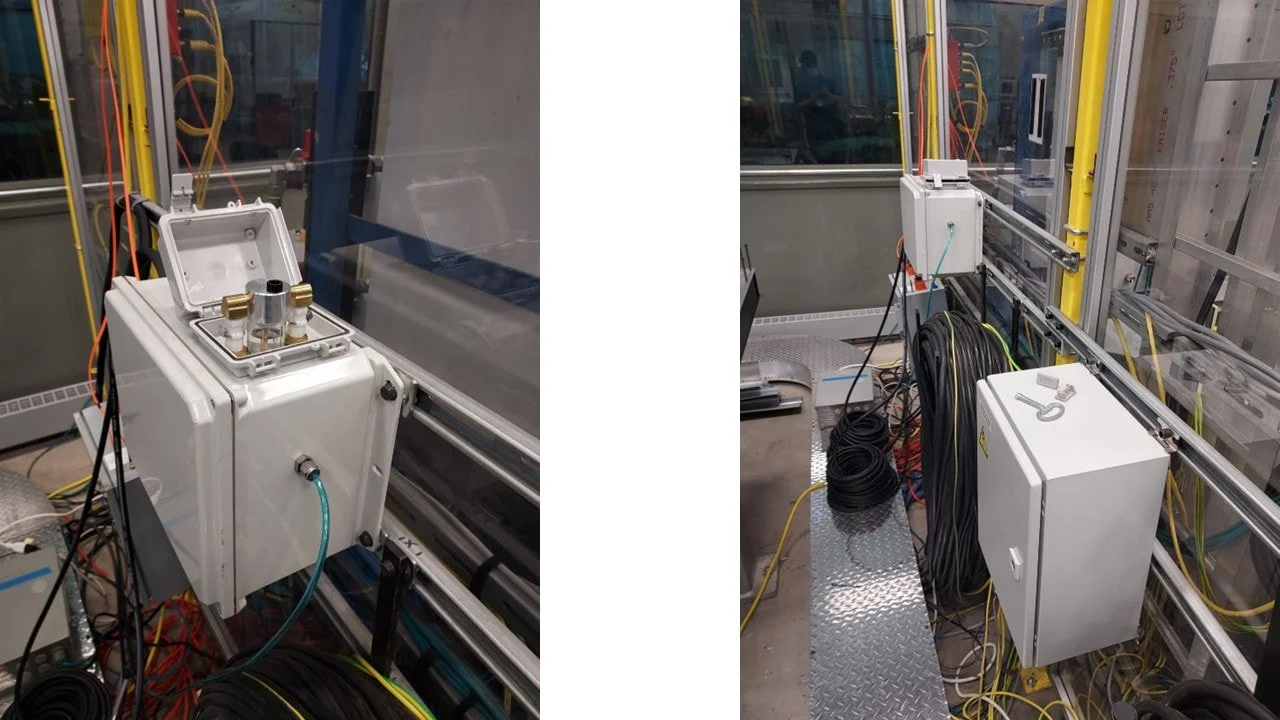

This slideshow describes the RADION atmospheric cold plasma jet using solid-state microwave applicators with direct precursor injection for plasma-enhanced chemical vapor deposition (PECVD).

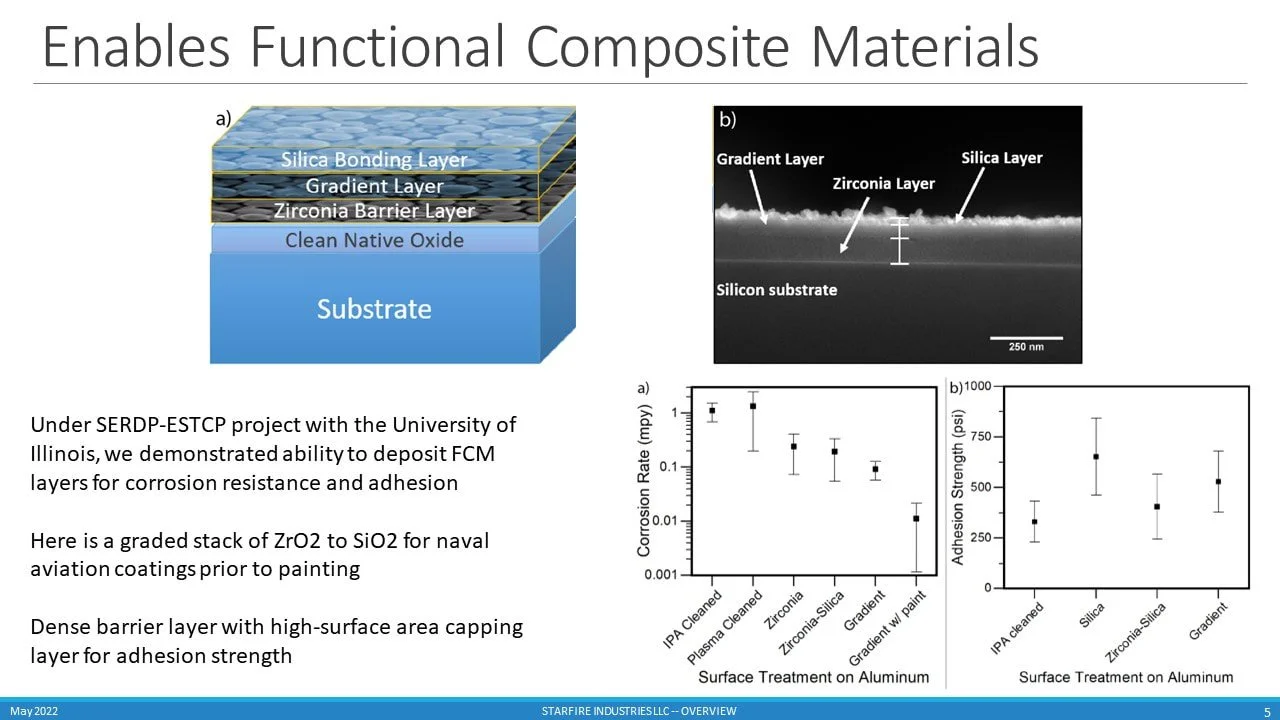

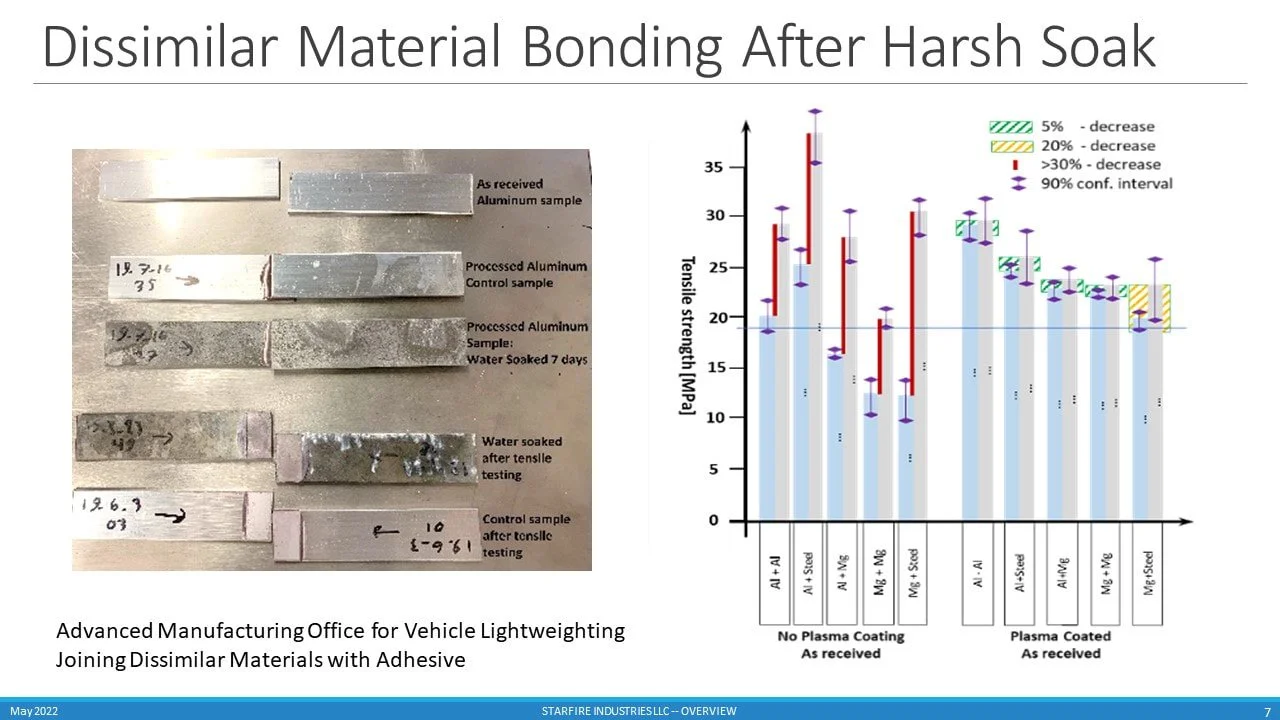

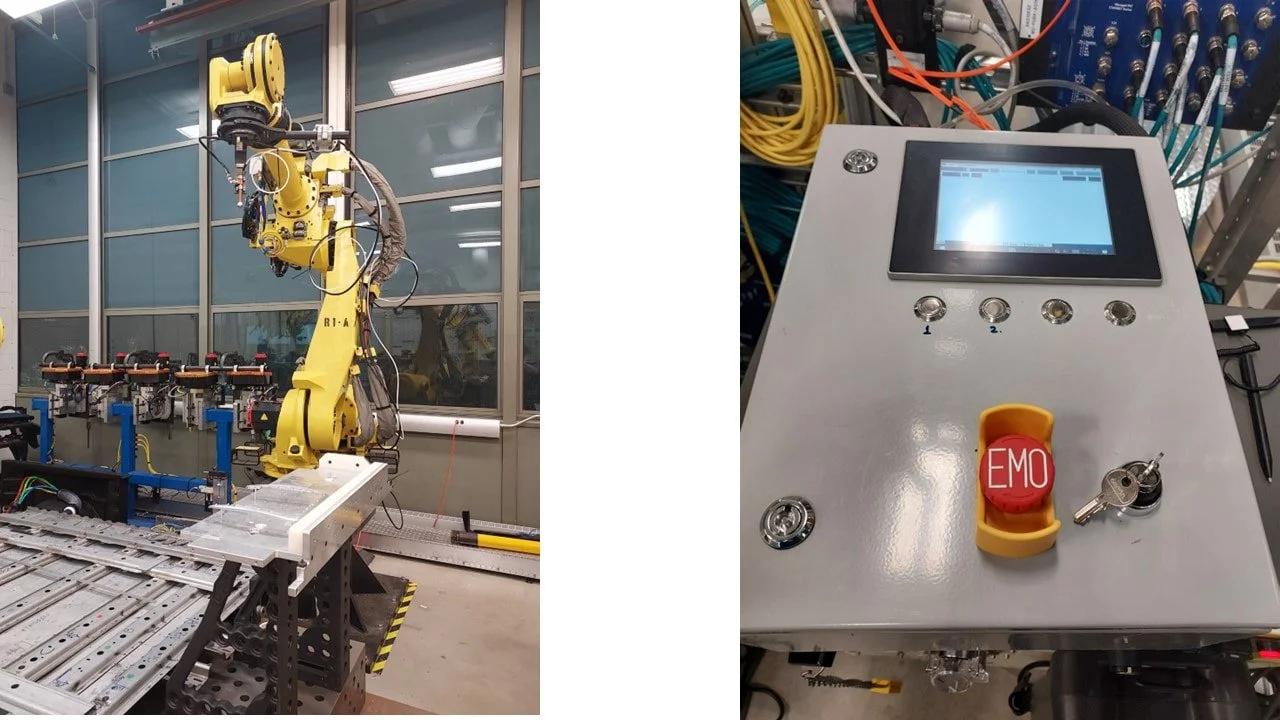

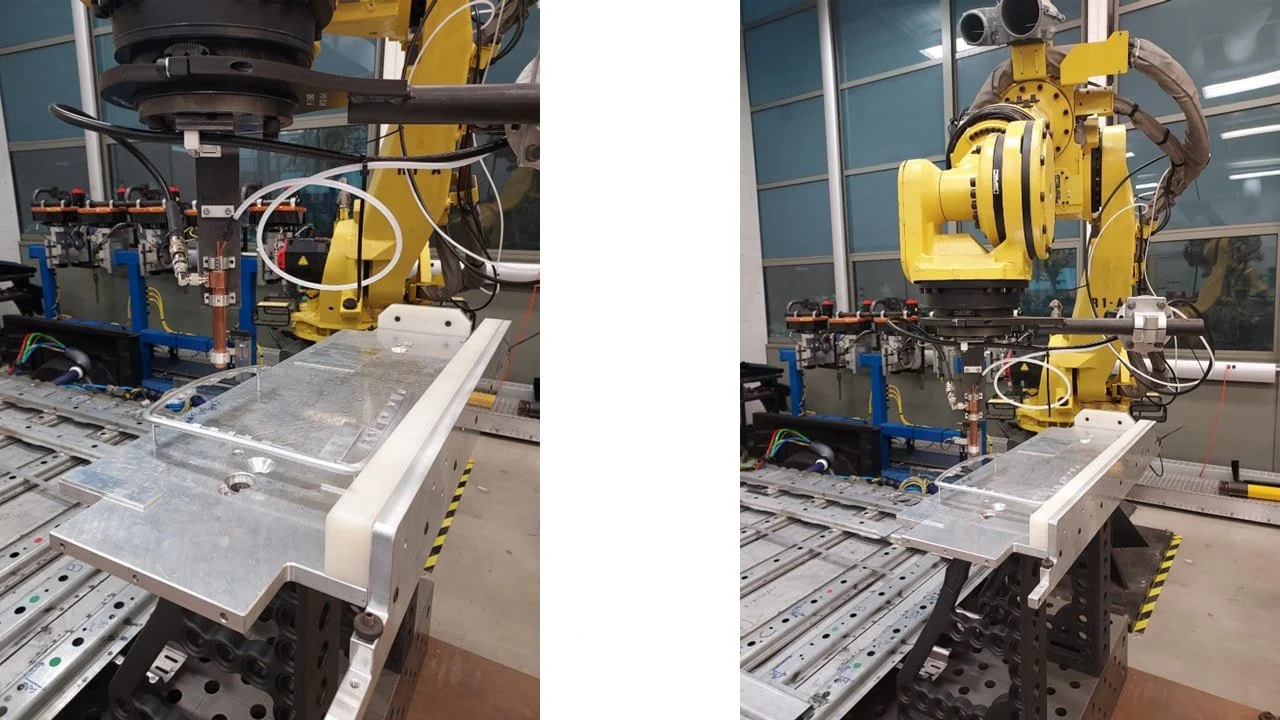

This system is being used for direct plasma cleaning, surface functionalization, graded material coating for corrosion-resistance and adhesion promotion, and reactive activation and surface sealing. The RADION was successfully used for point-of-manufacturing treatment of dissimilar materials prior to adhesive bonding between Mg, Al, CFRP, stainless-steel and other composite materials.

Starfire worked with the Applied Research Institute, the Center for Plasma-Material Interactions, and General Motors LLC for this technical demonstration.