IMPULSE® Next Generation HiPIMS

Protect the unprotected with patented Starfire technology.

Opening Doors to New Applications

IMPULSE 2kW & 20kW pulsed power modules are plug-n-play with existing hardware and our innovative ultra-fast pulsing topology with Positive Kick™ increases deposition rate, higher ion % fraction, and user-controlled ion energy to the substrate for deposition and etching -- all in one system.

Starfire's patented technology has opened the doors to new application spaces such as At-C, metals on plastics, corrosions/wear & semi.

Impulse 2-2

for R&D and both low & high volume production

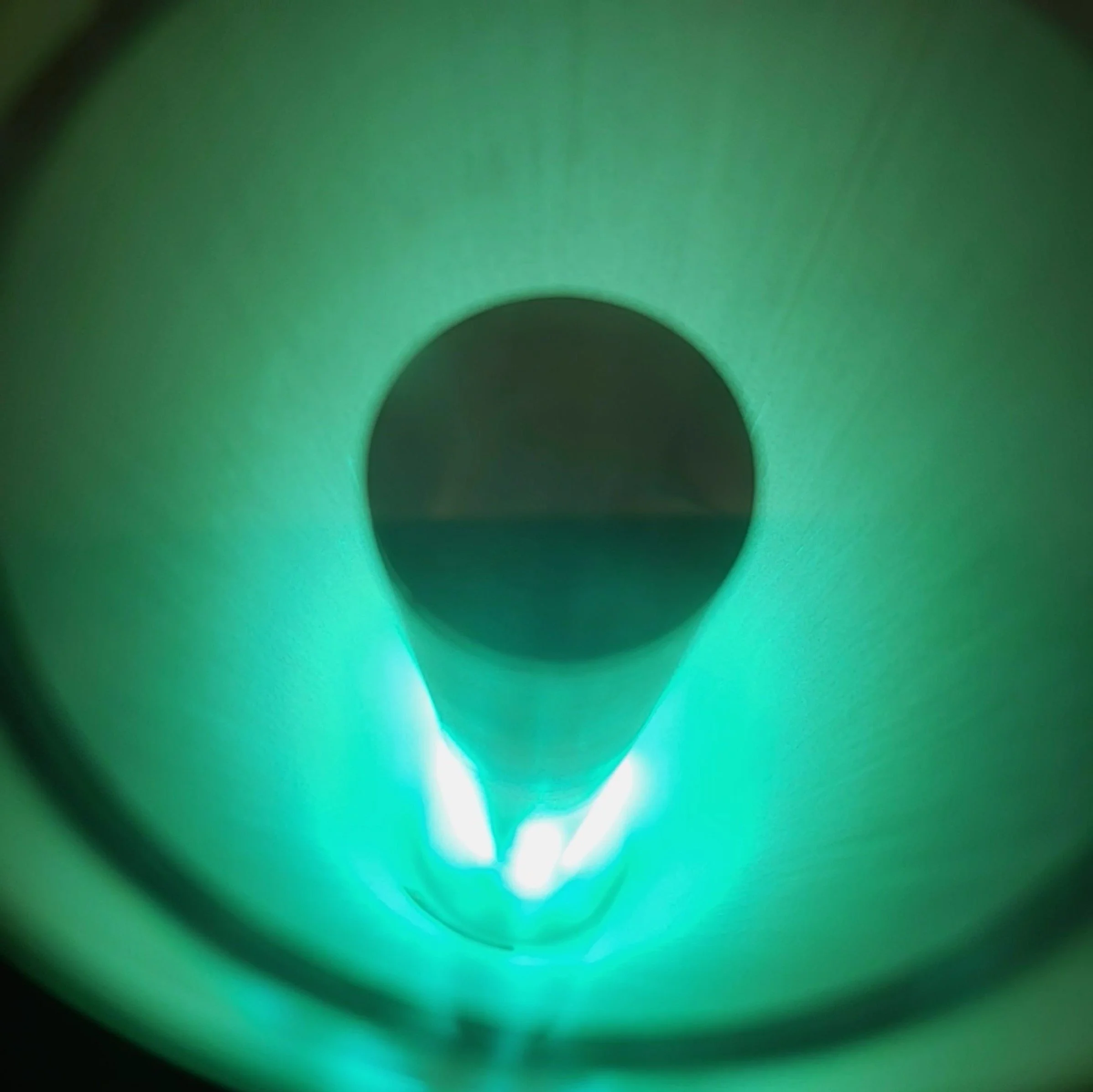

The Starfire Industries IMPULSE 2-2 is an affordable and versatile pulsed power module that converts a conventional DC sputtering system into a ultra-fast HiPIMS system.

The IMPULSE 2-2 thin-film coating solution is ideal for small 1” to 4” cylindrical and linear cathodes providing high ionization fraction and independent control of ion energy to “dial-in” film stress and morphology.

IMPULSE 2-2 in the news at Kurt J. Lesker

"A Postive Kick™ Enhances the High Power Impulse Magnetron Sputter Process."

Innovative Magnetrons For Production HiPIMS Processing

in-line O.D. coatings on tubes, fibers, extruded shapes, amd strips, e.g. nuclear fuel cladding, high-temperature superconducting tapes, optical fibers, etc.

batch I.D. coatings on cavities, pipes and 3D shapes, e.g. superconducting RF cavities, flexible cryogenic bellows, etc.

Our engineers developed and patented specialized HiPIMS magnetrons optimized for IMPULSE + Positive Kick for:

Game-changing IMPULSE Technology

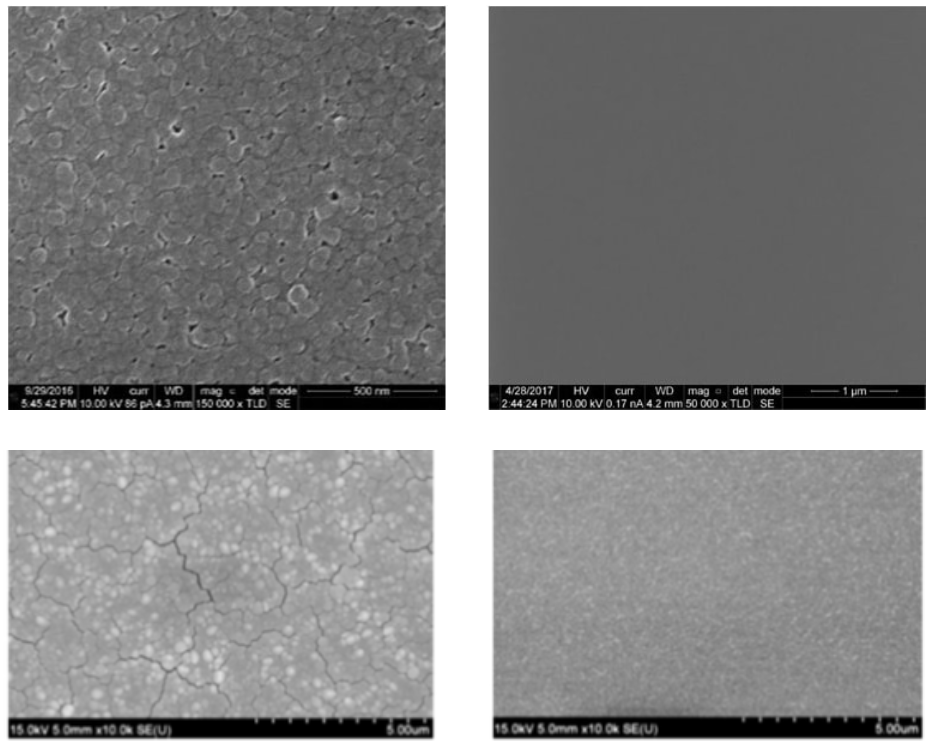

High-performance density. High-hardness. Non-porous Films. Superior Optical Coatings.

Key Features of the IMPULSE

Innovative ultra-fast pulsing topology with Positive Kick increases deposition rate, higher ion % fraction, and user-controlled ion energy to the substrate for deposition and etching all in one system

Access high current densities >>1 A/cm2 with precision control of ion energy for film stress control

Enable wider processing window for reactive HiPIMS and deposition on insulating substrates.

Affordably enables HiPIMS deposition on existing magnetrons with existing DC power supplies.

Master/slave synchronization of multiple magnetrons or substrate biases with precision timing

Multiple modules can be tied together to drive a single cathode at higher output power

RJ45 ports for computer control through telnet interface and

serial communications

The Positive Kick Results

Game-changing technology for coatings

Precision control on ion energy (eV-level) for sputter epitaxy

Brings HiPIMS deposition to glass, ceramics & plastics

Enables stress-relieved super-thick (>100 micron) coatings

Achieve fully-dense quasi-conformal coatings on 3D structures

Enable functional, graded nanocomposite layering

High sp3 nano-smooth hydrogen-free diamond coatings!

Ideal for oxide, nitride, carbide optical display & wear resistance

Simultaneous deposition and etching in one system

Dr. David Ruzic honored with the 2020 Gaede-Langmuir Award

“For the invention and commercialization of physical vapor deposition magnetrons and power supplies specifically for high-power impulse magnetron sputtering”